Geochem sample preparation and shipping services.

- LGSI recognize sample preparation as a critical path in mineral exploration and mine assay

- processes.

- The facility has the requisite equipment to process various sample types such as Drill core,

rock chips, rocks, soils, sediment, vegetation etc. - Our aim is to provide high quality sub-sample for geochemical analysis using best

industrial practices including client specific request - To reduce your transport and logistics cost and improve TAT.

- To give a better storage to your pulp and coarse reject samples for future reference.

- To provide you with an easy accessibility to the lab for audits.

Sample Reception

It’s spacious for storage, secured, easy to track sample and keep a better chain of custody

Sorting and Weighing

Accounting for your samples, taking note of discrepancies, logging and capturing individual sample weight using calibrated balances to ensure accuracy of data.

Drying Trays

Preparing samples for drying using clean drying trays to prevent contamination.

Drying Oven

Loading samples for drying under controlled Temperature based on sample type to ensure samples integrity is kept throughout the process chain.

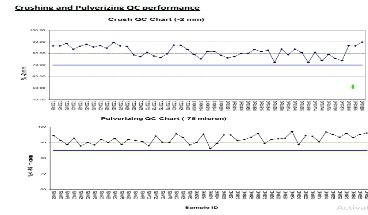

Crushing and Pulverizing

Stages of particle size reduction and quality testing to ensure

best analyte recovery.

The facility has the capacity to process 10000 to 15000 samples per month

Splitting and Pulverizing

Ensuring representative samples split and homogenisation

Dust Extractor and Compressed air system

Efficient Contamination control systems for your samples quality

QC Chart

Monitoring of sample preparation quality performance during crushing and pulverizing – Ensuring pulp samples meet desired quality

Coarse Reject Storage

Spacious and Fenced storage of reject samples

while awaiting collection.

New Equipment

Reducing your logistics cost and improving turn-around time